Figure 5-1c depicts a typical field-welded HSS to gusset plate connection. The effective area shall be the ef-.

1 Typical Unreinforced Hss To Hss Moment Connection Download Scientific Diagram

DESIGN OF WELDED CONNECTIONS AWS D112000 2423 Minimum Length.

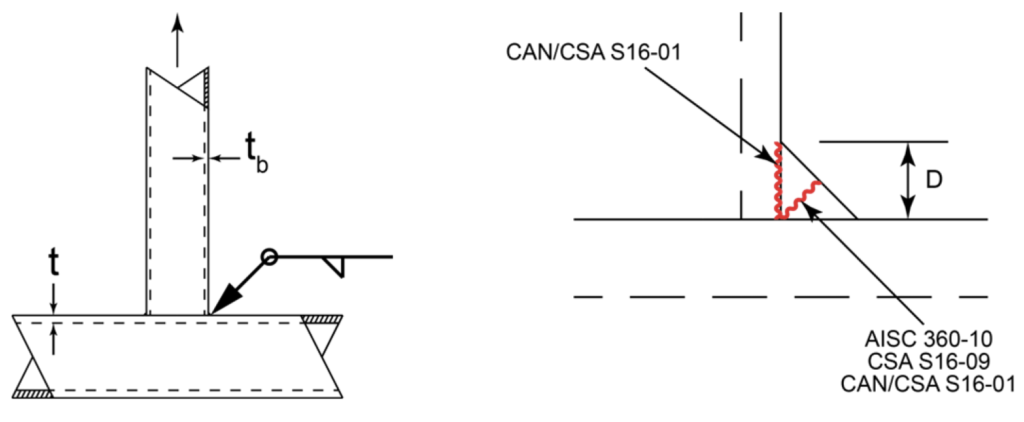

. The minimum effective length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length. AISC Connections Section NJ and AISC Manual Part 9 HSS and Box Member Connections Section NK Selecting Standard Connections from the AISC Manual AISC Manual Parts 9 10 Seismic Connection BMA Engineering Inc. The gusset is welded to the HSS in the slot and the project- ing portion of the gusset is similar to the stem of the end tee connection.

K with two or three branches in a. Table 1-7D Square HSS Brake Pressed Compactness criteria Table 1-8 Round HSS Table 1-9 Pipe. BOLTS ARE FOR ALIGNMENT PURPOSES ONLY.

11 7 3 1-0 1 8 STRINGER TO PLATFORM- TYP. TYPICAL E70XXELECT X Q. HSS Design with the Latest Codes.

And if the bolted connection is inevitable then the fewer bolts the better. STAIR TO INTERMEDIATE PLATFORM - TYPICAL CONNECTION. The fewer connections visible the better.

Directly Welded Truss Connection K Connection TY Connection. Hollow structural sections HSS. This specification never appeared in the Manual of Steel Construction but it did appear in the HSS Connections Manual.

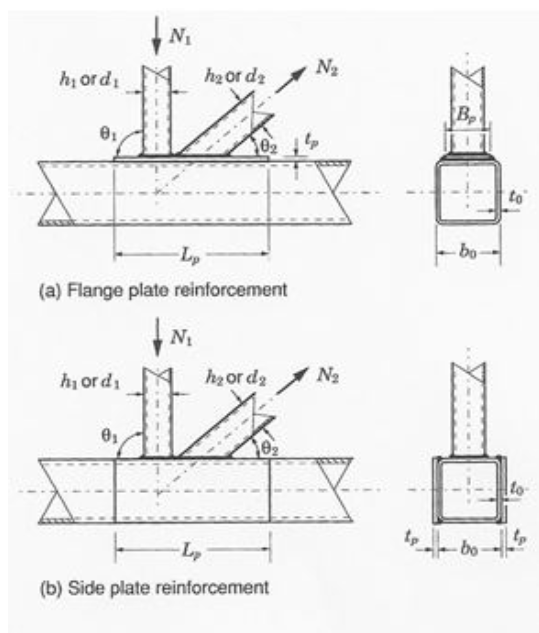

For the unmatched connection the beam was an HSS 12x8x38 β 08 suggesting that plastification of the column face may be a concern. STRUCTURAL STAINLESS STEEL. For the matched connection the beam was an HSS 12x10x38 β 10 allowing the loads to be transferred directly into the sidewall.

The types of connections are. To attach the end plate to the HSS. The design wall thickness t shall be taken equal to 093 times the nominal wall thickness for electric-resistance-welded ERW HSS and equal to the nominal thickness for submerged-arc-welded SAW HSS ERW HSS produced to ASTM A500 and A53.

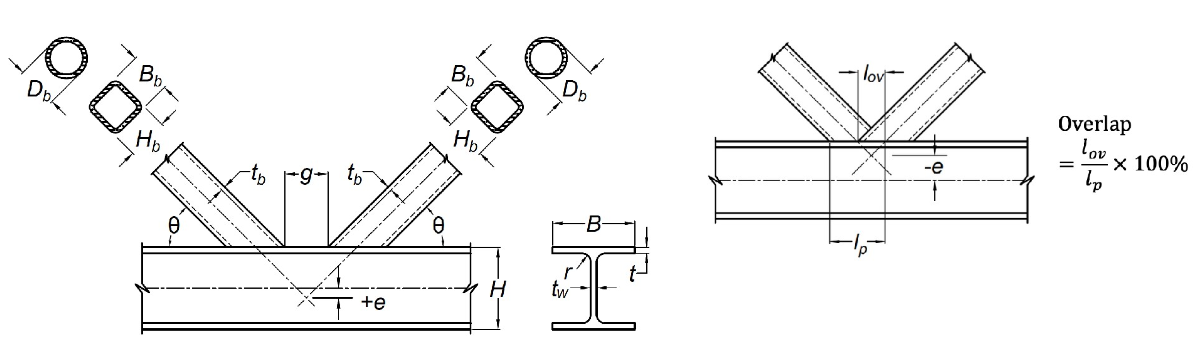

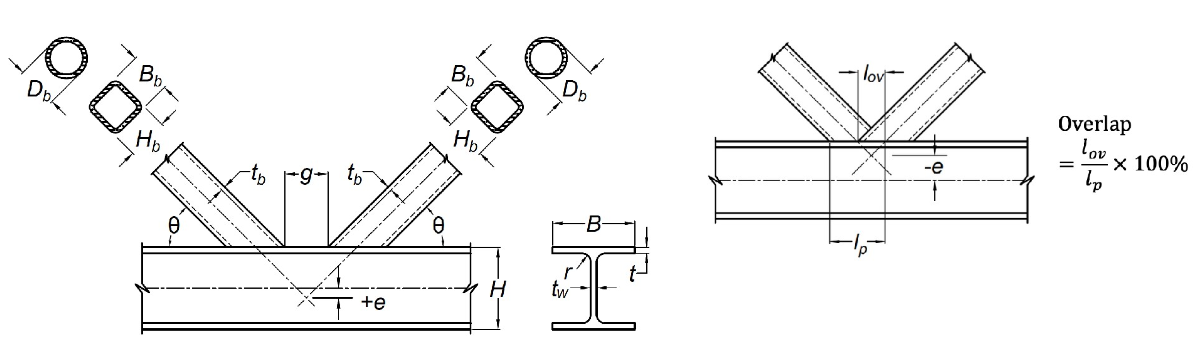

STAIR MUST BE WELDED TO PLATFORM AFTER INSTALL. Another type of end connection is the slotted HSSgusset plate connection shown in Figure 5-1b. 10112 HSSToHSS Truss Connections HSStoHSS truss connections are defined as connections that consist of one or more branch members that are directly welded to a continuous chord that passes through the connection and shall be classified as follows.

Built for connection design our proprietary software has undergone years of development and extensive peer review. Table 1-1 W-Shapes Welded Table 1-2A S-Shapes Welded Table 1-2B S-Shapes Hot Rolled. RXCD produces calculations for over 100 projects a year and is continually expanding the number of licensed states.

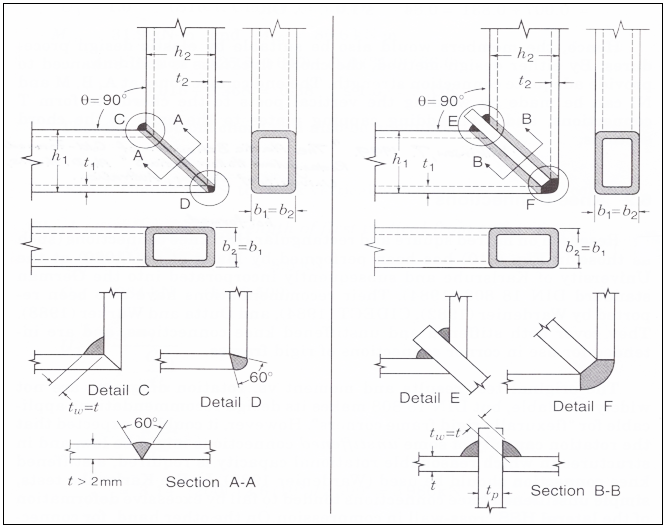

Welded HSS-to-HSS connections are typically used in trusses to connect branch members to main members with welds around the perimeter of the branch. T or Y with a single branch perpen-dicular or at an angle to the main member. DESIGN TABLES IN ACCORDANCE WITH AISC DG27.

If the connection is needed then the welded one is desired more than the bolted one. RexConn Designs service area spans across North America including all 50 states and 5 Canadian territories. When dealing with the exposed bearing structure hollow structural sections HSS are desired more than open sections.

The directly welded connections utilized prequalified CJP welds as specified in AWS D11 2010.

Hss Welded To Hss Structural Engineering General Discussion Eng Tips

Hss To Hss Connections Steel Tube Institute

Welded Truss Connections Between Hss Branches And I Shaped Chords Steel Tube Institute

Hss To Hss Welded Connection Side Matched Dimensions Structural Engineering General Discussion Eng Tips

Hss End Connection Welded From Three Sides Only Structural Engineering General Discussion Eng Tips

Stiffness Analysis W To Hss Moment Connection Idea Statica

0 comments

Post a Comment